Technological process

The manufacturing of wires and cables is completely different from that of most mechanical and electrical products. Mechanical and electrical products are usually assembled into parts by another part, and then assembled into a single product by multiple parts. The products are measured by the number of sets or pieces. The basic unit of measurement of wire and cable is length. All wires and cables are made of wire and cable products by adding insulation, shielding, cabling, protective layer, etc. layer by layer on the periphery of the conductor. The more complex the product structure is, the more layers are superimposed.

Process characteristics

1、 The influence of large-length continuous superposition combination production mode on wire and cable production is global and controllable, which involves and affects:

(1) Production process flow and equipment layout

All kinds of equipment in the production workshop must be reasonably discharged according to the process flow required by the product, so that the semi-finished products in each stage can be transferred in sequence. For equipment configuration, the production capacity shall be balanced according to different production efficiency. Some equipment may have to be configured with two or more to balance the production capacity of the production line. Therefore, the reasonable selection and combination of equipment and the layout of production site must be balanced and comprehensively considered according to products and production capacity.

(2) Production organization management

The production organization and management must be scientific, reasonable, thorough, accurate, strict and meticulous. The operator must implement the process requirements meticulously. Any problem in any link will affect the smoothness of the process flow and the quality and delivery of products. Especially for multi-core cables, if the length of a pair or basic unit is short, or there is a quality problem, the length of the whole cable will be insufficient, resulting in scrapping. On the contrary, if the length of a unit is too long, it must be sawn away, resulting in waste.

(3) Quality management

The production mode of continuous superposition and combination of large length will cause a problem in any link and instant in the production process, which will affect the quality of the whole cable. The more quality defects occur in the inner layer and are not found in time to stop production, the greater the loss. Because the production of wires and cables is different from assembled products, they can be disassembled, reassembled and replaced; The quality problem of any part or process of wire and cable is almost irreparable and irreparable to this cable. The subsequent treatment is very negative, either sawing short or degrading treatment, or scrapping the whole cable. It cannot be disassembled and reassembled.

The quality management of wires and cables must run through the whole production process. The quality management inspection department shall conduct patrol inspection, operator self inspection and mutual inspection of upper and lower processes throughout the production process, which is an important guarantee and means to ensure product quality and improve the economic benefits of the enterprise.

2. There are many production processes and large material flow

Wire and cable manufacturing involves a wide range of processes, from smelting and pressure processing of non-ferrous metals to chemical technologies such as plastics, rubber and paint; Textile technology such as wrapping and weaving of fiber materials, wrapping of metal materials, longitudinal wrapping of metal strip, metal forming and processing technology of welding, etc.

All kinds of materials used in the manufacture of wires and cables not only have many categories, varieties and specifications, but also have a large number. Therefore, the consumption, reserve consumption, batch cycle and batch of various materials must be verified. At the same time, the decomposition, recycling, reuse and waste disposal of waste products, as an important content of management, do a good job in material quota management and pay attention to saving.

In the production of wire and cable, from the import and export and storage of raw materials and various auxiliary materials, the circulation of semi-finished products in each process to the storage and delivery of products, the material flow is large, so it must be reasonably arranged and dynamically managed.

3. Many special equipment

Wire and cable manufacturing uses special production equipment with process characteristics of the industry to meet the structure and performance requirements of cable products and meet the requirements of large-length continuous and high-speed production as much as possible, thus forming a series of special equipment for cable manufacturing. Such as extruder series, drawing machine series, stranding machine series, wrapping machine series, etc.

The manufacturing technology of wires and cables is closely related to the development of special equipment and promotes each other. New process requirements to promote the emergence and development of new special equipment; On the contrary, the development of new special equipment has improved and promoted the popularization and application of the new process. Such as wire drawing, annealing, extrusion series line; Special equipment such as physical foaming production line promotes the development and improvement of wire and cable manufacturing process, and improves the product quality and production efficiency of cable.

2、 Main process of wire and cable

Wires and cables are manufactured through three processes: drawing, twisting and coating. The more complex the model and specification, the higher the repeatability.

1. Drawing

In metal pressure processing, the technical processing method of forcing the metal through the die (pressing wheel) under the action of external force, compressing the metal cross-sectional area and obtaining the required cross-sectional area shape and size is called metal drawing.

Drawing process is divided into single wire drawing and twisted drawing.

2. Stranding

In order to improve the flexibility and integrity of wires and cables, more than two single wires are intertwined in the specified direction, which is called stranding.

Stranding process includes conductor stranding, cabling, weaving, steel wire armor and winding.

3. Coating

According to different performance requirements for wires and cables, special equipment is used to coat different materials on the outside of the conductor. Coating process points:

A. Extrusion: rubber, plastic, lead, aluminum and other materials.

B. Longitudinal package: rubber, wrinkled aluminum strip material.

C. Wrapping: Ribbon paper tape, mica tape, alkali free glass fiber tape, non-woven fabric, plastic tape, linear cotton yarn, silk and other fiber materials.

D. Dip coating: insulating paint, asphalt, etc

-

2020-11-11

-

2020-11-11

-

2020-11-11

-

LAN Cable – CAT5e, FTP Series (shielded)

LAN cable

-

LAN Cable – CAT6, UTP Series (unshielded)

LAN cable

-

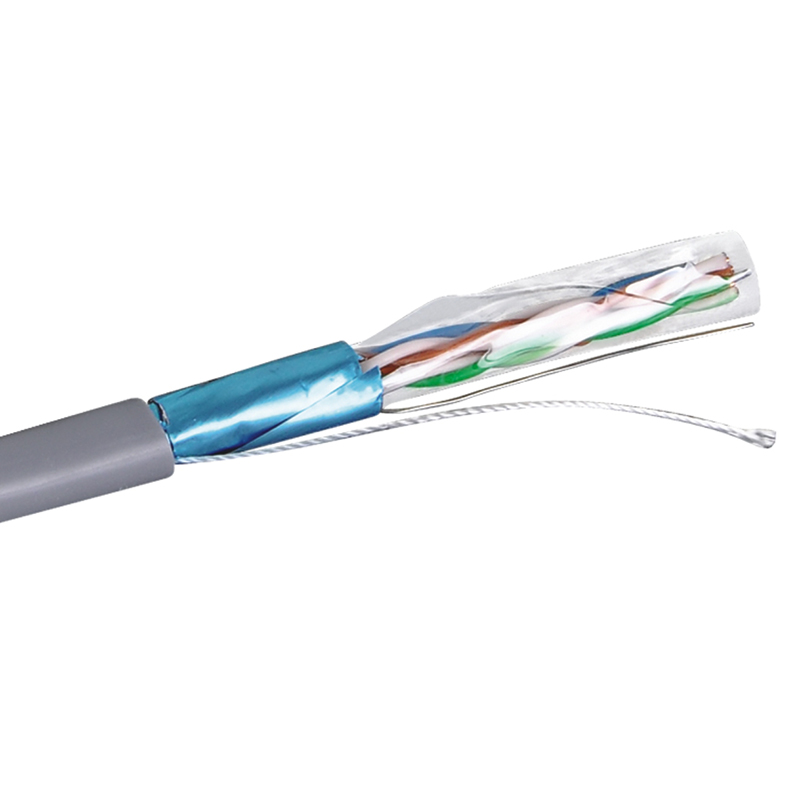

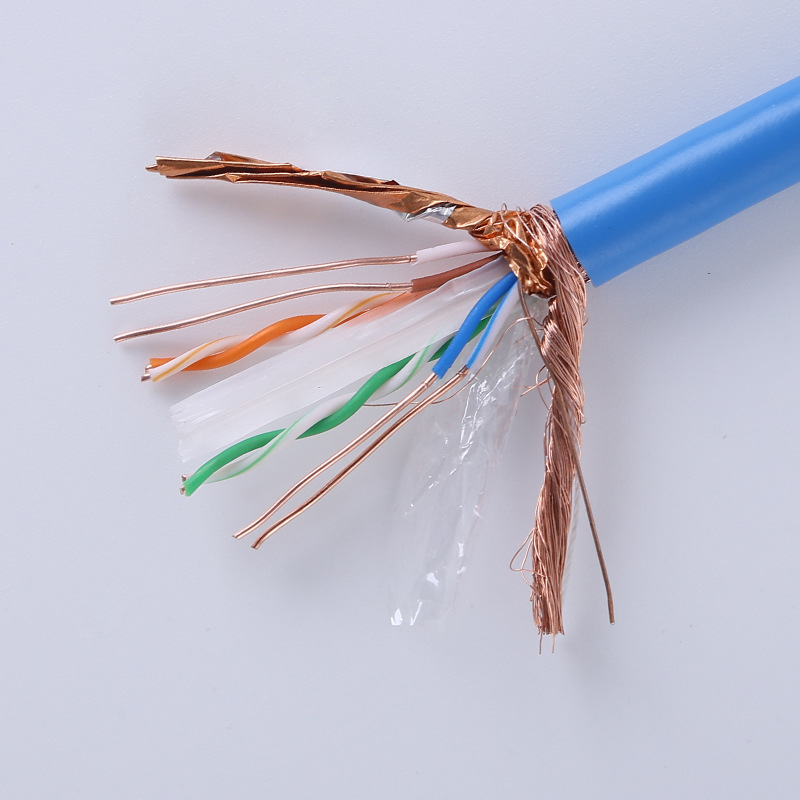

LAN Cable – CAT6, FTP Series (shielded)

LAN cable

-

LAN Cable – CAT3, Multi-pairs, UTP Series

LAN cable

-

LAN Cable – CAT5, Multi-pairs, UTP Series

LAN cable

-

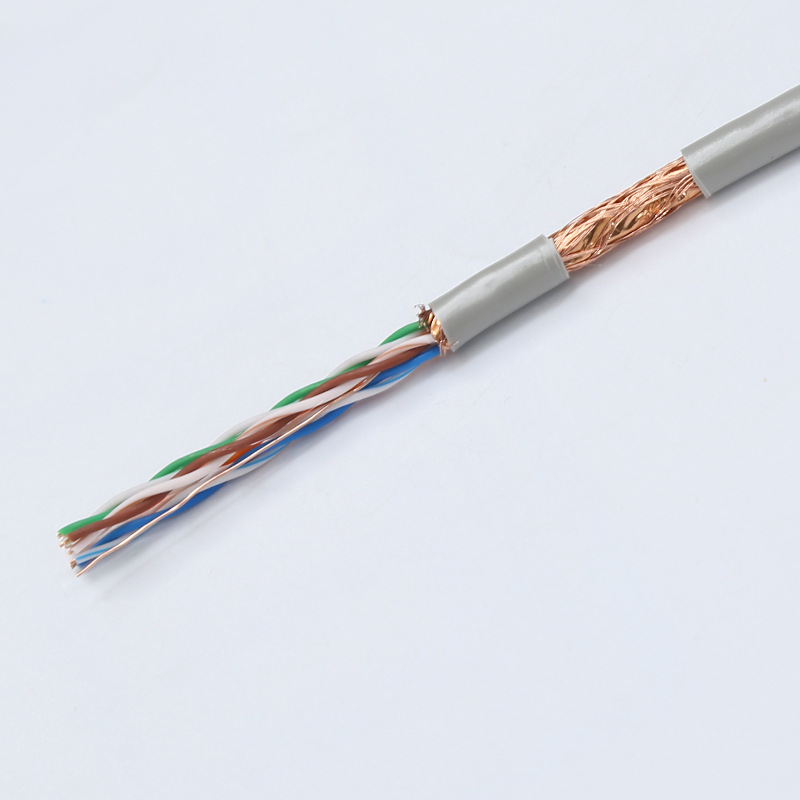

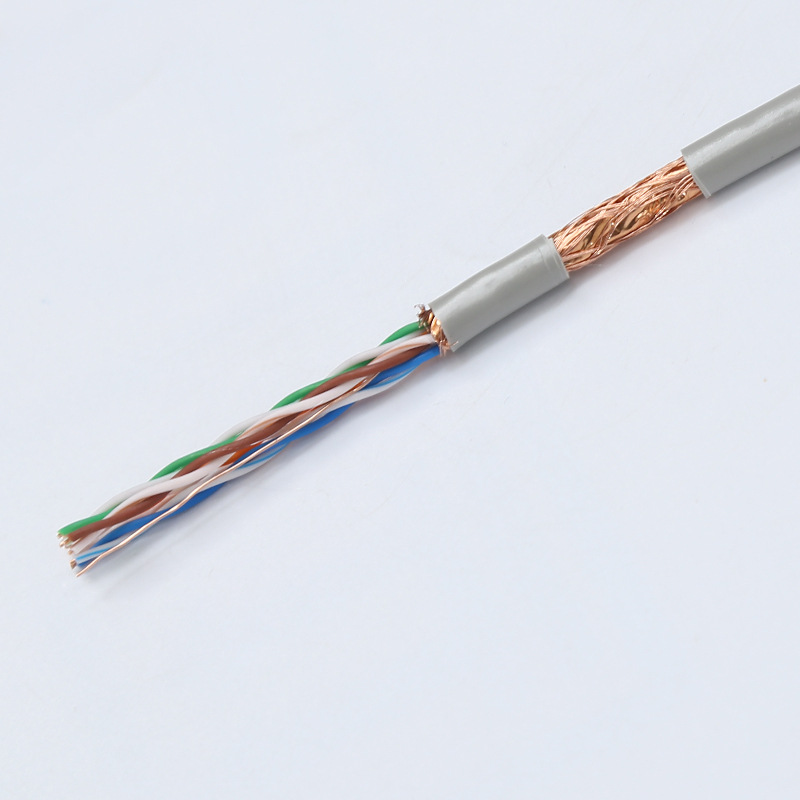

LAN Cable – CAT5e,4 pairs (double-shielded)

LAN cable

-

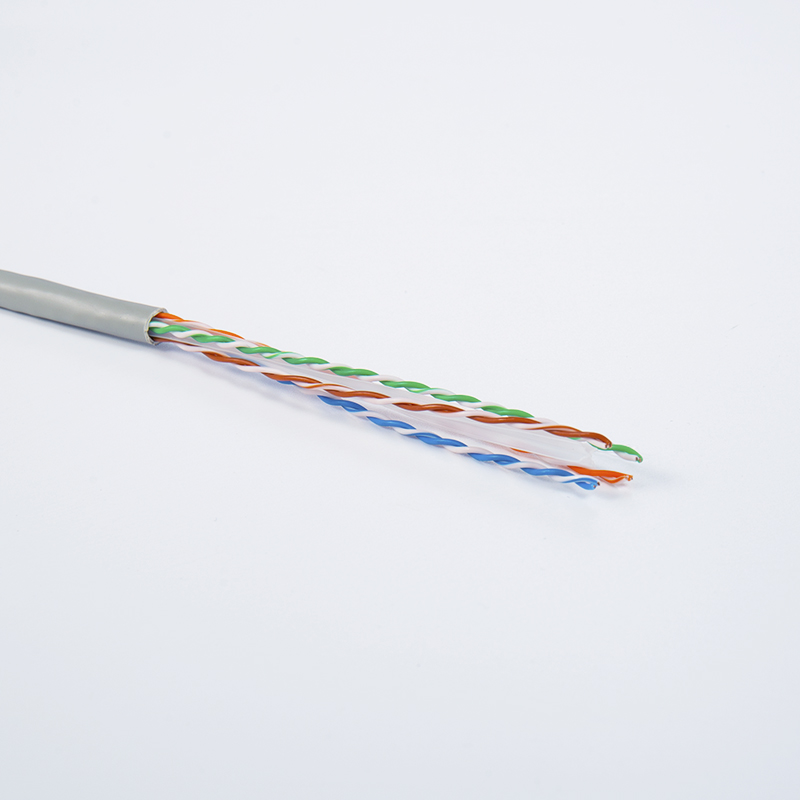

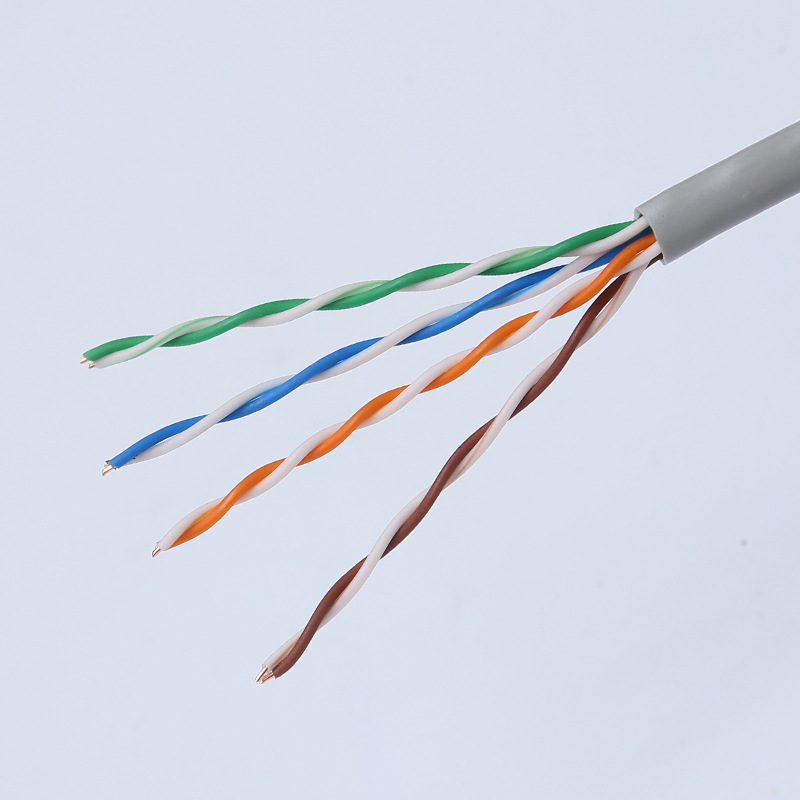

LAN Cable – CAT5e,4 pairs (un-shielded)

LAN cable

-

LAN Cable – CAT6e (double-shielded)

LAN cable