Cause of aging

1. External force damage. According to the operation analysis in recent years, especially in Pudong, Shanghai, where the economy is developing rapidly, a considerable number of cable problems are caused by mechanical damage.

2. Damp insulation. This condition is also very common. It usually occurs at the cable joint in the directly buried or row pipe. For example, unqualified cable joints and joints made under humid climate conditions will make the joints water or mixed with water vapor. For a long time R, water branches will be formed under the action of electric field, gradually damaging the insulation strength of cables and forming defects.

3. Chemical corrosion. If the cable is directly buried in the area with acid-base effect, the armor, lead skin or outer protective layer of the cable will often be corroded. The maintenance layer will be subject to chemical corrosion or electrolytic corrosion for a long time, resulting in the failure of the maintenance layer, reduced insulation and cable problems. Chemical: the cable corrosion of the unit is quite serious

4. Long term overload operation. During overload operation, due to the thermal effect of the current, the conductor will be heated when the load current passes through the cable. At the same time, the skin effect of the charge, the eddy current loss of the steel armor and the loss of insulating medium will also produce additional heat, which will increase the cable temperature.

5. There is something wrong with the cable joint. The cable joint is the thinnest link in the cable line. The cable joint defects caused by direct personnel errors (poor construction) often occur. In the process of manufacturing cable joints, if there are reasons such as loose joint crimping and insufficient heating, the insulation of cable head will be reduced, resulting in accidents.

6. Environment and temperature. The external environment and heat source where the cable is located will also cause excessive cable temperature transition, insulation breakdown, and even explosion and fire.

Common faults

Common faults of cable lines include mechanical damage, insulation damage, insulation moisture, insulation aging and degeneration, overvoltage, cable overheating, etc. When the above faults occur in the line, cut off the power supply of the faulty cable, find the fault point, stop inspection and analysis of the faults, and then stop repair and experiment. The power supply can be restored only after the faults are eliminated.

The most direct cause of cable fault is breakdown due to reduced insulation

It mainly includes:

a. Overload operation. Long term overload operation will increase the cable temperature, aging the insulation, cause insulation breakdown and reduce the construction quality

b. The electrical aspects include: the construction process of cable head fails to meet the requirements, the sealing performance of cable head is poor, moisture invades into the cable, and the insulation performance of cable decreases; Failure to take maintenance measures during cable laying, damaged maintenance layer and reduced insulation

c. Civil Engineering: the drainage of the well pipe trench is not smooth, and the cable is soaked in water for a long time, damaging the insulation strength; The shaft is too small, the bending radius of the cable is not enough, and it is damaged by extrusion external force for a long time. It is mainly due to the mechanical barbaric construction in municipal construction, which damages and breaks the cable

d. Corrosion. The maintenance layer is subject to chemical corrosion or cable corrosion for a long time, resulting in the failure of the maintenance layer and the reduction of insulation

e. The poor quality of the cable itself or the accessories of the cable head, the poor sealing of the cable head, the dissolution and cracking of the insulating glue lead to the resonance phenomenon of the station, which is the fault of line disconnection, so that the phase to phase capacitance and ground capacitance of the line form a resonance circuit with the excitation inductance of the distribution transformer, thus arousing ferromagnetic resonance.

-

2020-11-11

-

2020-11-11

-

2020-11-11

-

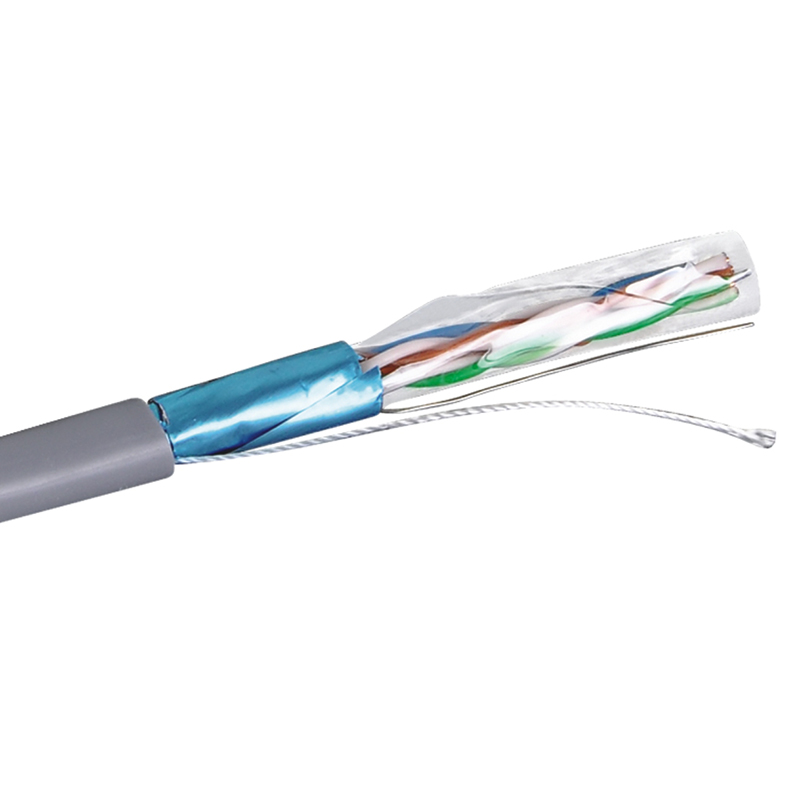

LAN Cable – CAT5e, FTP Series (shielded)

LAN cable

-

LAN Cable – CAT6, UTP Series (unshielded)

LAN cable

-

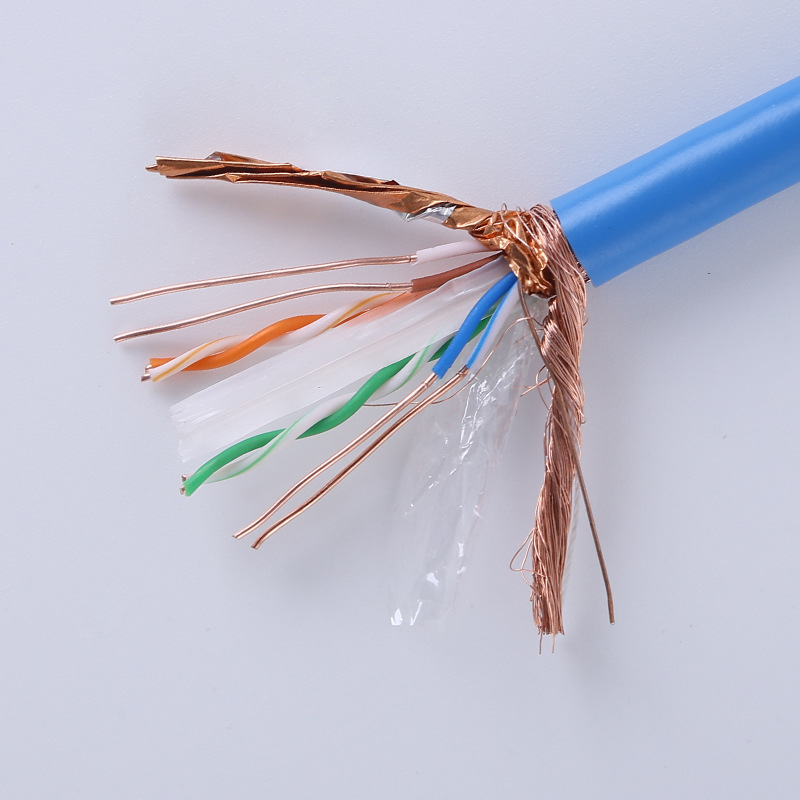

LAN Cable – CAT6, FTP Series (shielded)

LAN cable

-

LAN Cable – CAT3, Multi-pairs, UTP Series

LAN cable

-

LAN Cable – CAT5, Multi-pairs, UTP Series

LAN cable

-

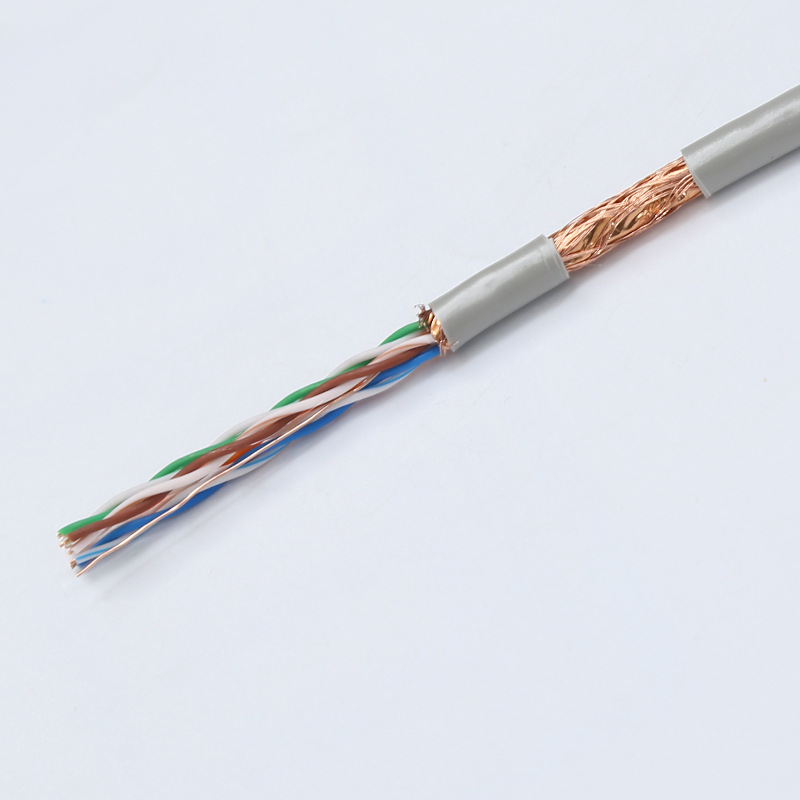

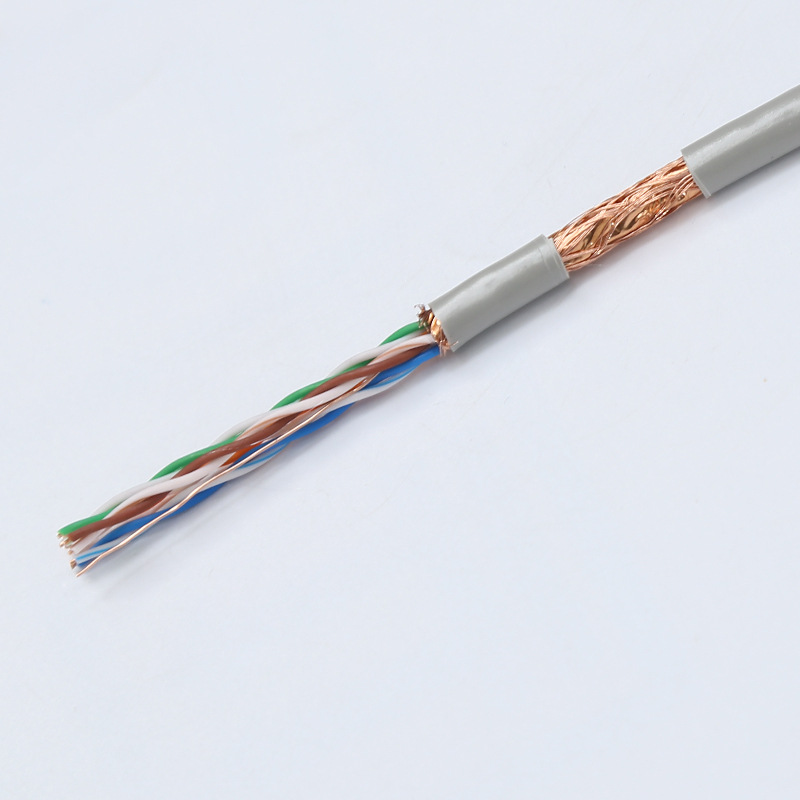

LAN Cable – CAT5e,4 pairs (double-shielded)

LAN cable

-

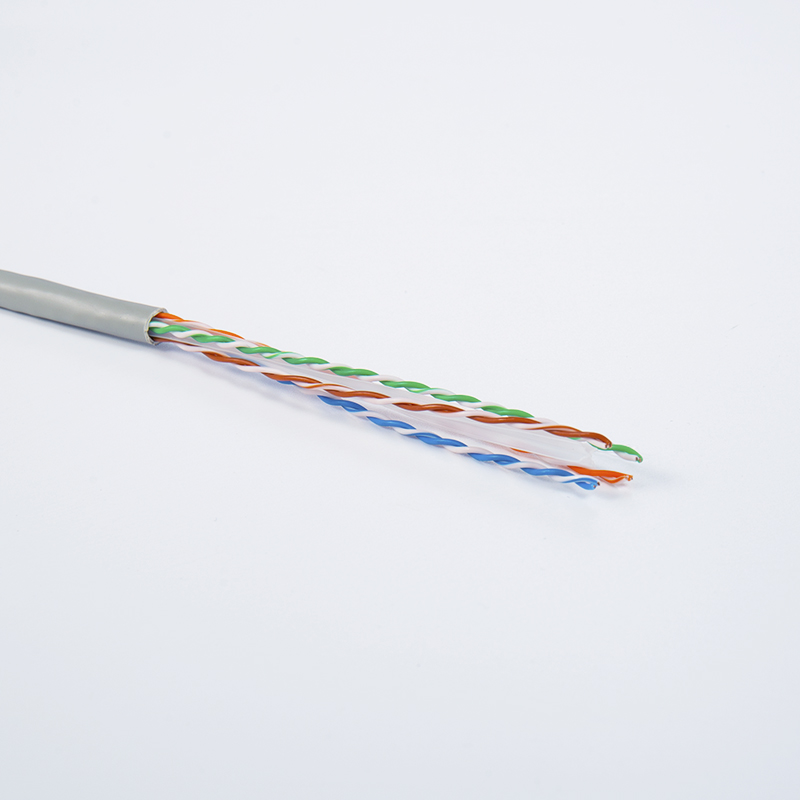

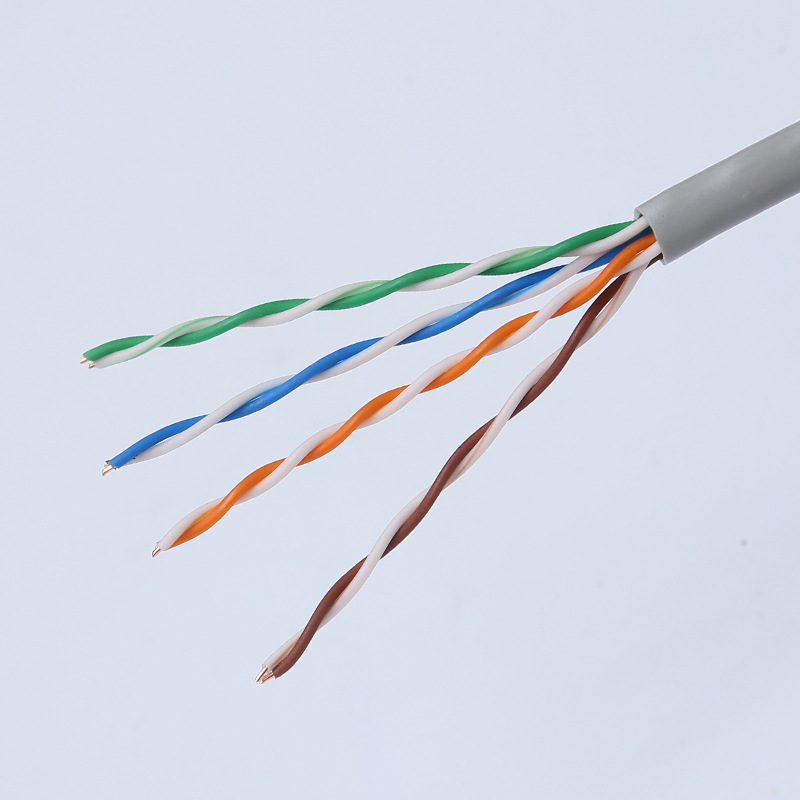

LAN Cable – CAT5e,4 pairs (un-shielded)

LAN cable

-

LAN Cable – CAT6e (double-shielded)

LAN cable