Copper wire and aluminum wire can be connected together in a certain way. Copper wire and aluminum wire are made of different materials, so their characteristics are also different. It needs special treatment to connect them together. So why can't copper wire and aluminum wire be connected directly? How to connect copper wire and aluminum wire? Why can't copper wire and aluminum wire connect directly?

-The resistivity of, aluminum wire and copper wire is different.

2、 This is the key, that is, the aluminum wire is easy to oxidize in the air and forms a layer of oxide on its surface. In addition, the hardness of aluminum is smaller than that of copper, which will greatly increase the contact resistance at the connection between aluminum wire and copper wire. When the current passes through this connection, the contact resistance will heat. If it is a large current, the heating will be very serious and the connection will be burned.

3、 According to the safe operation standard, aluminum wire cannot be connected with copper wire.

Results of direct connection between copper wire and aluminum wire:

1. When the copper and aluminum conductors are directly connected, the contact surface of the two metals can easily form an electrolyte under the action of moisture, carbon dioxide and other impurities in the air, so as to form a primary battery with aluminum as the negative electrode and copper as the positive electrode, which causes electrochemical corrosion of aluminum and increases the contact resistance at the junction of copper and aluminum.

2. In addition, because the elastic modulus and thermal shrinkage coefficient of copper and aluminum are very different, after repeated cold and heat cycles (power on and power off) during operation, a large gap will be generated at the contact point, which will affect the contact and increase the contact resistance. With the increase of contact resistance, the temperature will rise during operation. Under high temperature, corrosion and oxidation will intensify, resulting in a vicious circle, which will further deteriorate the connection quality, lead to excessive temperature transition at the contact point, and even smoke, burn and other accidents.

-

2020-11-11

-

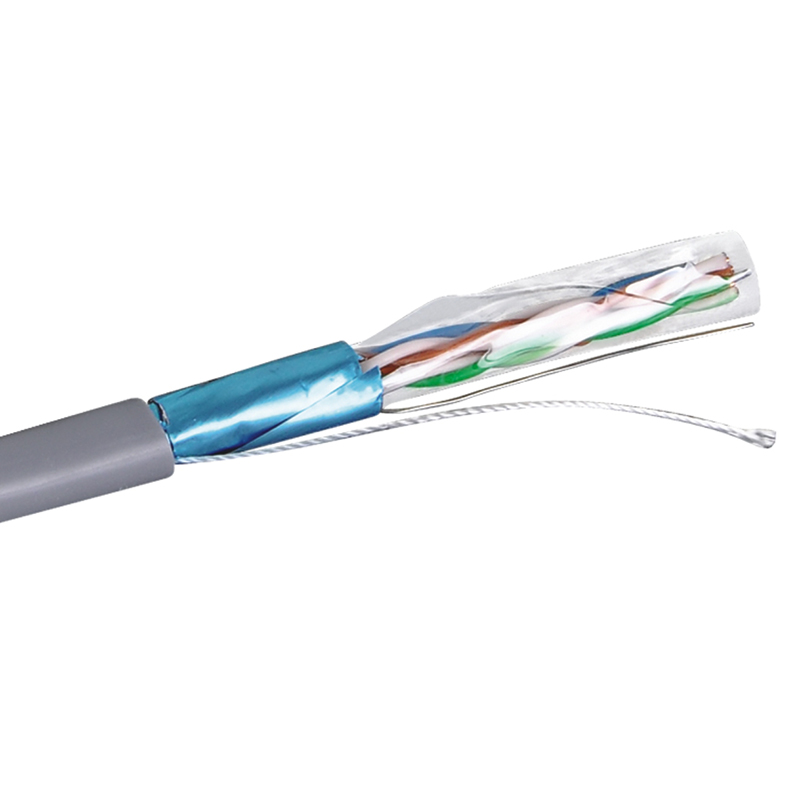

LAN Cable – CAT5e, FTP Series (shielded)

LAN cable

-

LAN Cable – CAT6, UTP Series (unshielded)

LAN cable

-

LAN Cable – CAT6, FTP Series (shielded)

LAN cable

-

LAN Cable – CAT3, Multi-pairs, UTP Series

LAN cable

-

LAN Cable – CAT5, Multi-pairs, UTP Series

LAN cable

-

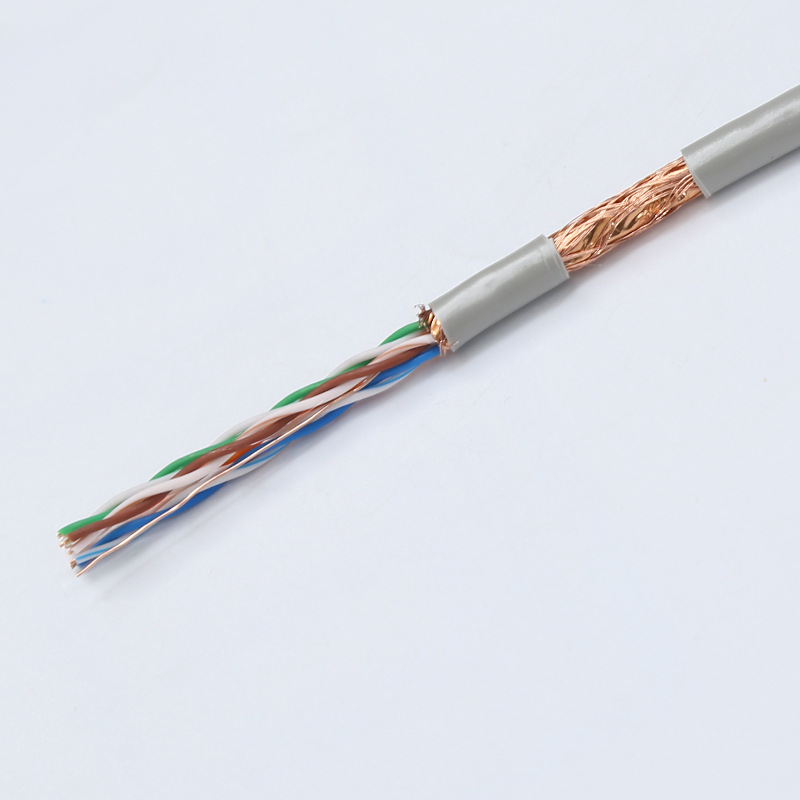

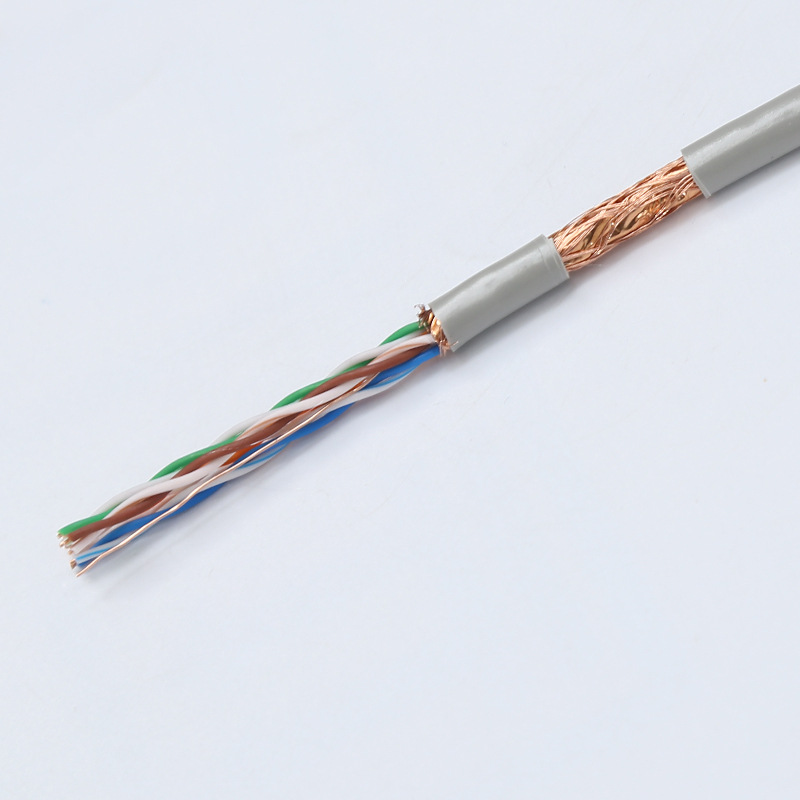

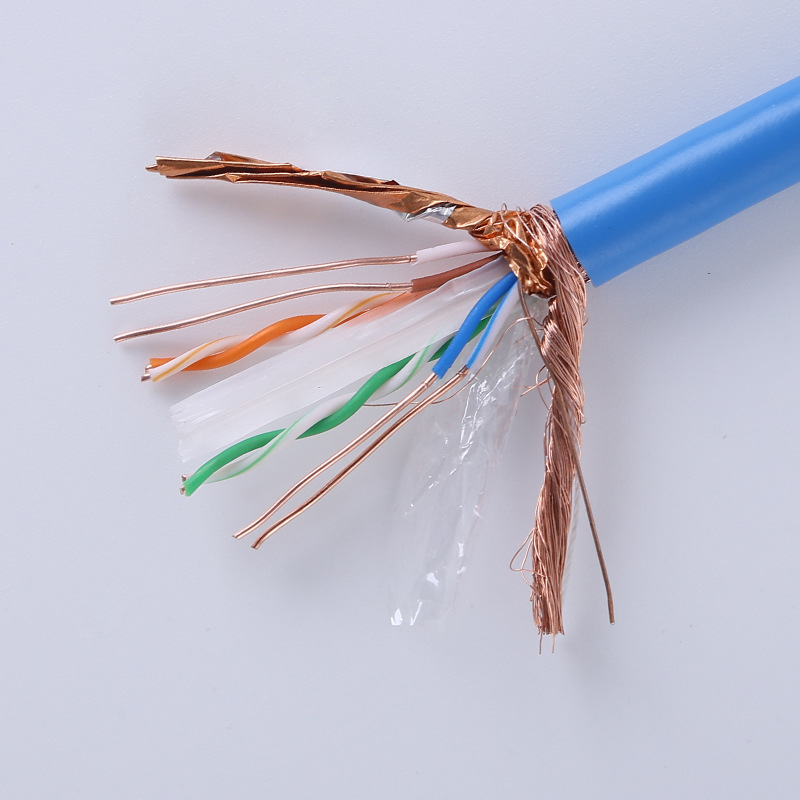

LAN Cable – CAT5e,4 pairs (double-shielded)

LAN cable

-

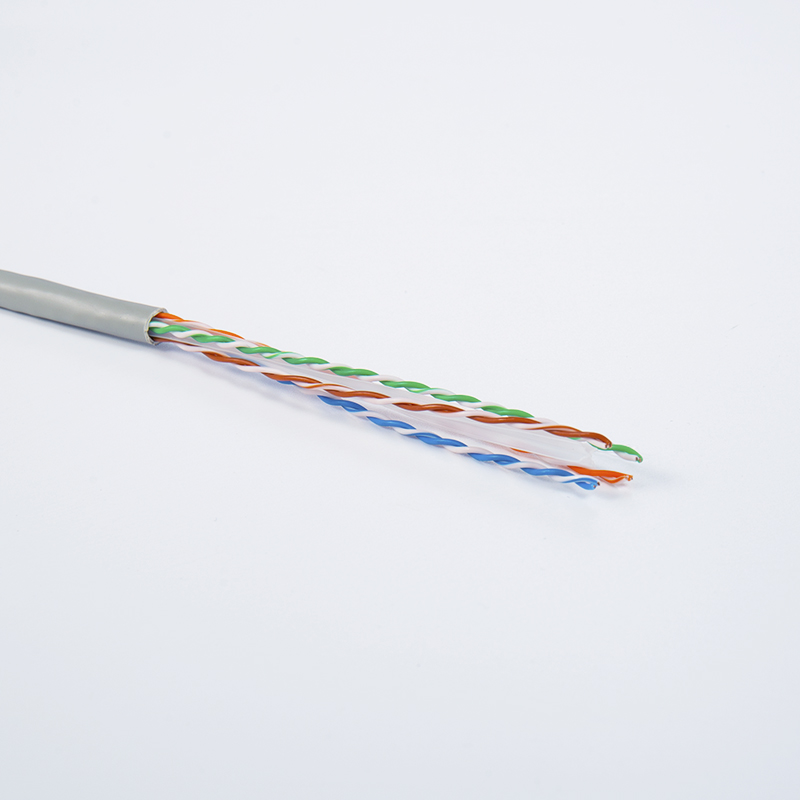

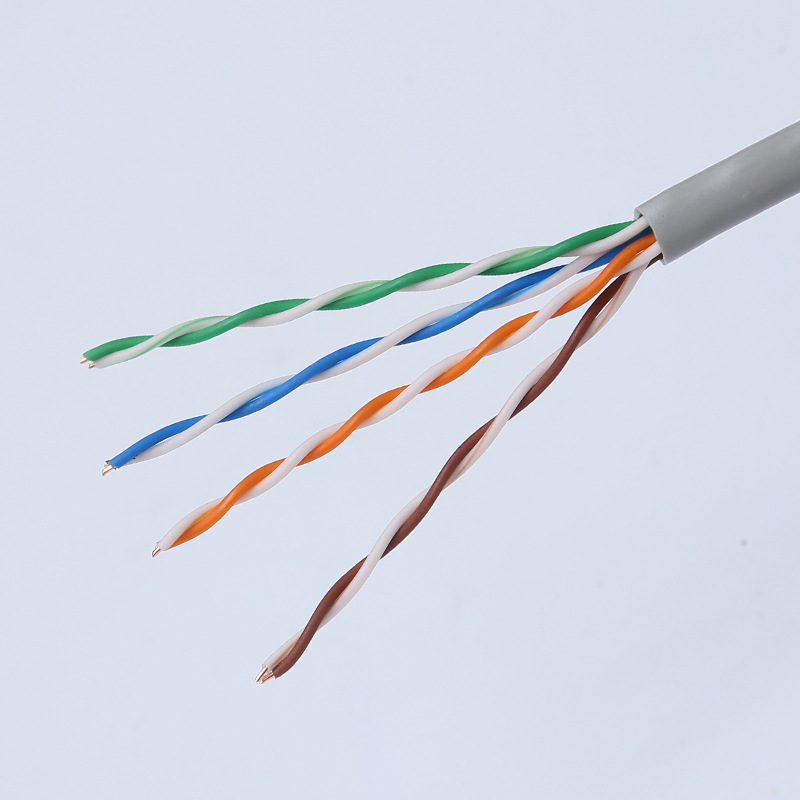

LAN Cable – CAT5e,4 pairs (un-shielded)

LAN cable

-

LAN Cable – CAT6e (double-shielded)

LAN cable